As the landscape of engineering continues to evolve, familiarity with various 3D printing techniques can significantly enhance an engineer’s toolkit. Understanding these methods helps in selecting the most suitable approach for specific projects, ultimately driving innovation. For more insights into creative strategies and approaches, explore our design tips and techniques.

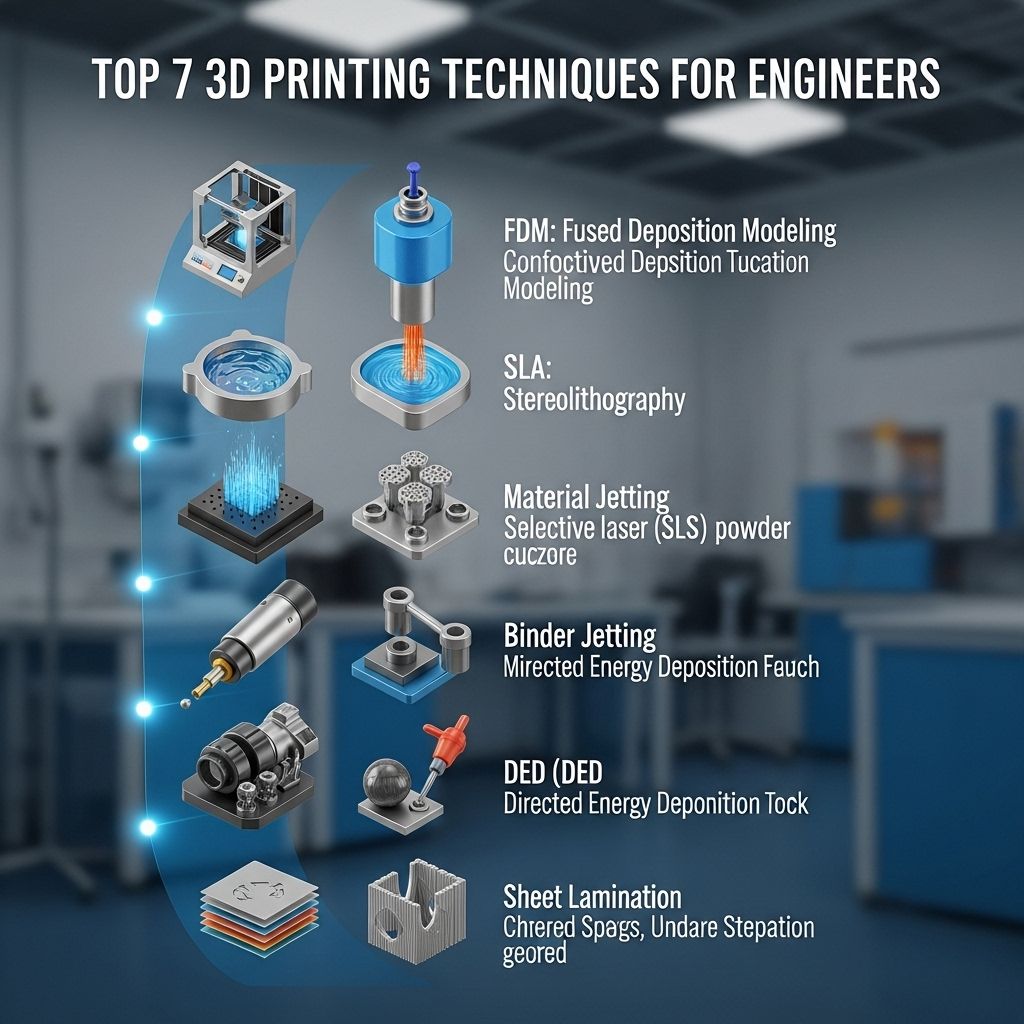

In the rapidly evolving world of technology, 3D printing has emerged as a revolutionary technique that has reshaped manufacturing, prototyping, and product development. For engineers, understanding the various 3D printing techniques is crucial to leverage this technology effectively. This article delves into the top seven 3D printing methods, emphasizing their applications, advantages, and limitations.

1. Fused Deposition Modeling (FDM)

FDM is one of the most popular 3D printing techniques, especially among engineers and hobbyists. It works by melting thermoplastic filaments and extruding them layer by layer to create a solid object.

Applications

- Prototyping

- Functional testing

- Low-volume production

Advantages

- Cost-effective

- Wide range of materials

- Easy to use and widely accessible

Limitations

- Surface finish may require post-processing

- Limited detail for complex geometries

2. Stereolithography (SLA)

SLA is a pioneering 3D printing technique that utilizes a laser to cure resin into hardened plastic. It is known for producing highly detailed and precise prints.

Applications

- Dental and medical models

- Jewelry design

- High-precision prototypes

Advantages

- Exceptional surface finish and detail

- Ability to create intricate geometries

- Faster than many other methods

Limitations

- Resins can be expensive

- Requires post-processing to remove supports

3. Selective Laser Sintering (SLS)

SLS employs a laser to fuse powdered material, typically nylon or polyamide, layer by layer to create durable parts. This method is particularly suitable for functional prototypes.

Applications

- Aerospace components

- Automotive parts

- Industrial tools

Advantages

- No need for support structures

- High strength and durability

- Versatile material options

Limitations

- Higher cost of equipment and materials

- Post-processing may be needed to improve surface finish

4. Digital Light Processing (DLP)

DLP is similar to SLA, but instead of using a laser, it uses a digital light projector to cure resin. This allows for faster printing times and is ideal for detailed models.

Applications

- Dental applications

- Rapid prototyping

- Small batch production

Advantages

- Faster than SLA

- High resolution

- Lower material waste

Limitations

- Limited material options compared to FDM

- Resin handling requires care and safety measures

5. Binder Jetting

Binder jetting utilizes a liquid binding agent that is selectively deposited onto layers of powder material. It’s particularly useful for creating large parts with minimal waste.

Applications

- Ceramic parts

- Metal parts

- Sand casting molds

Advantages

- Can produce large parts quickly

- Minimal material waste

- Compatible with a variety of materials

Limitations

- Lower mechanical properties compared to SLS

- Requires post-processing for strength and finish

6. Multi Jet Fusion (MJF)

MJF is an advanced 3D printing technology developed by HP that uses a binding agent and heat to fuse powdered materials. It is known for its speed and efficiency.

Applications

- Functional prototyping

- Production parts

- Customized products

Advantages

- High speed and efficiency

- Strong and durable parts

- Excellent detail and surface finish

Limitations

- Expensive materials and machines

- Requires a controlled environment

7. PolyJet Printing

PolyJet printing works by depositing photopolymer droplets layer by layer, which are then cured with UV light. It enables rapid production of high-resolution parts.

Applications

- Complex prototypes

- Multi-material parts

- Medical models

Advantages

- High accuracy and detail

- Ability to print in multiple materials and colors

- No need for support structures for many geometries

Limitations

- Higher operational costs

- Limited material variations compared to other methods

Conclusion

Understanding the various 3D printing techniques is essential for engineers seeking to harness the potential of additive manufacturing. Each method has its unique advantages and applications, making it vital to choose the right technique based on project requirements. As technology continues to advance, the possibilities with 3D printing will only expand, further driving innovation across various industries.

FAQ

What are the most common 3D printing techniques used by engineers?

The most common 3D printing techniques used by engineers include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), Digital Light Processing (DLP), Binder Jetting, and Material Jetting.

How does Fused Deposition Modeling (FDM) work?

FDM works by extruding melted thermoplastic filament through a nozzle, which is then deposited layer by layer to create a three-dimensional object.

What are the advantages of using Stereolithography (SLA)?

SLA offers high precision and smooth surface finishes, making it ideal for detailed prototypes and intricate designs. It also allows for a wide range of resin materials.

What materials can be used in Selective Laser Sintering (SLS)?

SLS primarily uses powdered materials, including nylon, polystyrene, and various metal powders, allowing for strong and functional parts.

What is the role of Digital Light Processing (DLP) in 3D printing?

DLP uses a digital light projector to cure liquid resin into solid parts layer by layer, similar to SLA, but typically offers faster print times.

Can engineers use 3D printing for end-use parts?

Yes, many 3D printing techniques, especially SLS and SLA, are capable of producing durable and high-quality end-use parts suitable for various applications.