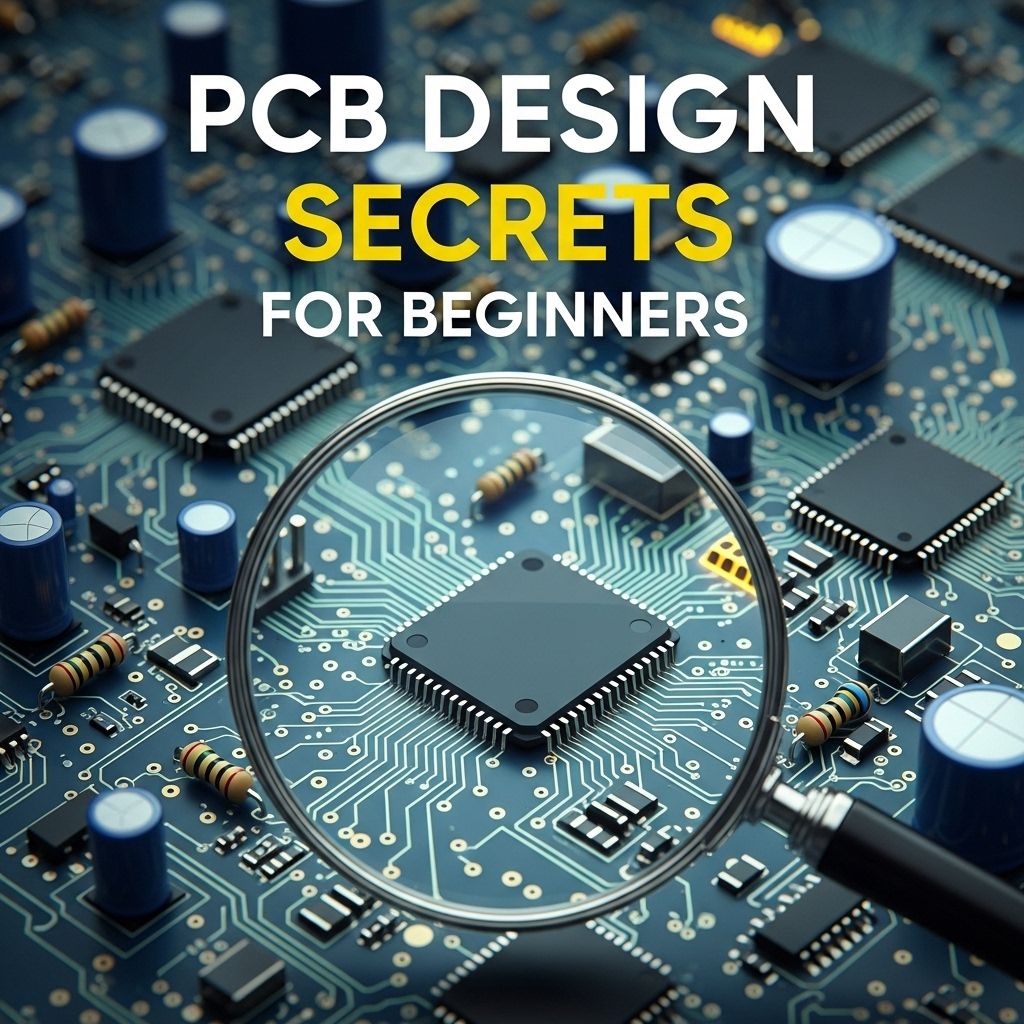

As you embark on your journey to master PCB design, understanding the foundational principles is key to success. This process can seem overwhelming for beginners, but with a solid roadmap and some modern graphic design ideas, you can simplify your approach and enhance your learning experience.

Designing a printed circuit board (PCB) can be an intimidating task for beginners, but it doesn’t have to be. With the right approach and knowledge, you can create effective PCB designs that meet your project requirements. This article aims to unveil the secrets of PCB design, providing a roadmap for novices eager to venture into the world of electronics.

Understanding the Basics of PCB Design

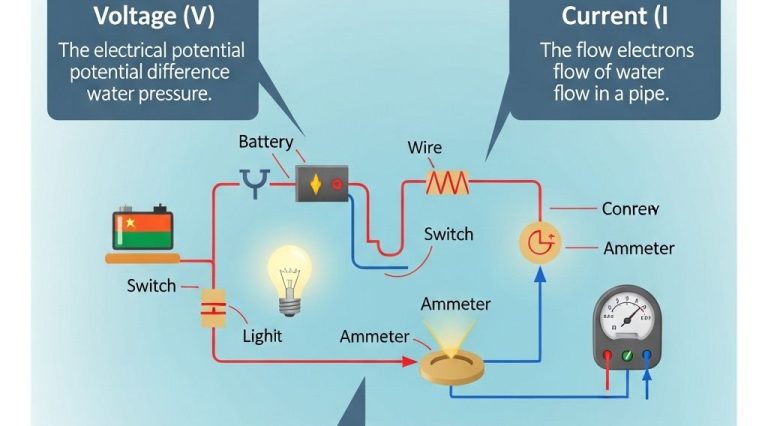

Before diving into the intricacies of PCB design, it’s essential to grasp some foundational concepts. A printed circuit board serves as the backbone of most electronic devices, supporting and connecting various components through conductive pathways.

What is a PCB?

A PCB is typically made from a non-conductive substrate like fiberglass, with copper traces that create electrical paths between components. The primary functions of a PCB include:

- Supporting electronic components

- Providing electrical connections

- Facilitating heat dissipation

The PCB Design Process

The design process can be broken down into several stages, each critical to the final product’s success.

1. Requirements Gathering

The first step is to define the requirements for your PCB project. Consider the following:

- Application: What will the PCB be used for?

- Size Constraints: What are the dimensions of the device?

- Power Requirements: How will power be distributed?

2. Schematic Design

Once you have your requirements, the next step is to create the schematic diagram. This is a representation of your electronic circuit, showing the connections between components. Utilize software tools like:

- Eagle

- KiCad

- Altium Designer

3. Component Selection

Choosing the right components is critical. Factors to consider include:

- Availability: Ensure components are readily available.

- Cost: Balance performance with budget constraints.

- Compatibility: Verify that components work together as intended.

4. Layout Design

With the schematic in hand, you can begin creating the PCB layout. This step involves positioning components and routing traces to connect them. Best practices include:

- Minimizing trace lengths to reduce resistance and inductance

- Grouping related components to enhance signal integrity

- Using ground planes for improved performance

5. Design Rules Check (DRC)

Before finalizing the design, perform a Design Rules Check (DRC) to ensure your PCB meets manufacturing standards. This step highlights any potential issues such as:

- Trace width violations

- Spacing violations between traces and pads

- Overlapping components

Key PCB Design Tips

Here are some essential tips to keep in mind during your PCB design process:

1. Keep It Simple

For beginners, it’s crucial to start with simple designs. Complexity can lead to mistakes and make troubleshooting difficult. As you gain experience, gradually increase the complexity of your designs.

2. Learn from Others

Consult existing designs and learn from them. Analyze open-source projects or designs shared by the community to understand best practices and common pitfalls.

3. Use Simulation Tools

Simulation tools can help visualize how your circuit will perform before manufacturing. Tools like SPICE allow you to simulate the behavior of your circuit, helping to identify issues early.

Common Mistakes to Avoid

Every beginner makes mistakes, but being aware of common pitfalls can help you avoid them:

- Neglecting to account for component tolerances

- Forgetting to label your schematic clearly

- Failing to check for thermal issues, especially in power circuits

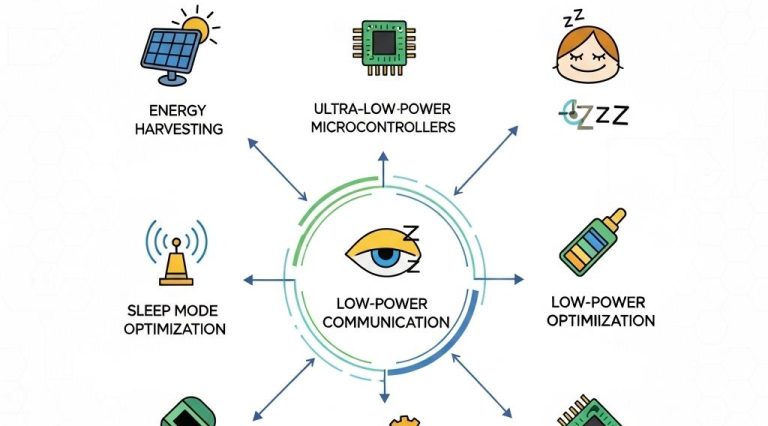

Advanced PCB Design Considerations

As you become more proficient in PCB design, consider these advanced topics:

1. Multilayer PCBs

For complex circuits requiring more connections, multilayer PCBs can be beneficial. They allow for denser designs and can help with routing signals more effectively.

2. Signal Integrity

Understanding signal integrity is crucial for high-speed designs. Factors such as trace width, impedance matching, and layout can significantly affect performance.

3. Design for Manufacturability (DFM)

Implementing DFM principles can streamline production and reduce costs. Considerations include:

- Minimizing the number of layers

- Using standard component sizes

- Ensuring that solder mask and silkscreen layers are optimized

The Future of PCB Design

Advancements in technology are continuously reshaping PCB design. Emerging trends include:

- Flexible PCBs for wearable technology

- Integration of RF components for IoT devices

- Increased emphasis on eco-friendly materials and processes

Conclusion

PCB design is an exciting and rewarding field that combines creativity and technical expertise. By understanding the fundamentals, avoiding common mistakes, and continually learning, beginners can unlock the potential of electronic designs and pave the way for innovative projects. Remember, the journey of a thousand miles begins with a single step—so start designing today!

FAQ

What are the basic principles of PCB design for beginners?

The basic principles of PCB design include understanding the schematic, choosing the right materials, ensuring proper layout for signal integrity, and following design rules for trace width and spacing.

What software can I use for PCB design as a beginner?

Popular PCB design software for beginners includes EasyEDA, KiCad, and Eagle. These tools offer user-friendly interfaces and tutorials to help you get started.

How do I choose the right components for my PCB?

Choosing the right components involves understanding your circuit requirements, considering factors like voltage, current, size, and availability, and ensuring compatibility with your design.

What is the importance of a good layout in PCB design?

A good layout is crucial in PCB design as it affects the performance, reliability, and manufacturability of the board. Proper routing of traces and placement of components can minimize interference and signal loss.

How can I prevent common mistakes in PCB design?

To prevent common mistakes in PCB design, always double-check your schematic, follow design rules, keep traces short and direct, and use proper grounding techniques.

What are some tips for routing traces on a PCB?

When routing traces on a PCB, keep them as short and direct as possible, avoid sharp corners, use wider traces for high currents, and maintain a consistent spacing between traces.