In mechanical engineering, having the right tools is essential for optimizing the design and production processes. As technology advances, engineers must stay informed about the latest innovations and methodologies. For practical insights, check out our collection of design tips and techniques that can help streamline workflows and enhance project outcomes.

In the world of mechanical engineering, the right tools can make all the difference in the design, analysis, and production process. With the rapid advancement of technology, the landscape of essential tools keeps evolving. Understanding and utilizing these tools effectively can enhance productivity, improve accuracy, and drive innovation. In this article, we will explore ten indispensable tools that every mechanical engineer should have in their toolkit, ranging from traditional instruments to cutting-edge software.

1. CAD Software

Computer-Aided Design (CAD) software is fundamental in the field of mechanical engineering. It allows engineers to create 2D and 3D models, analyze designs, and simulate performance under various conditions. Some of the most popular CAD software options include:

- AutoCAD

- SolidWorks

- CATIA

- Fusion 360

These tools not only facilitate design but also improve collaboration among team members and stakeholders.

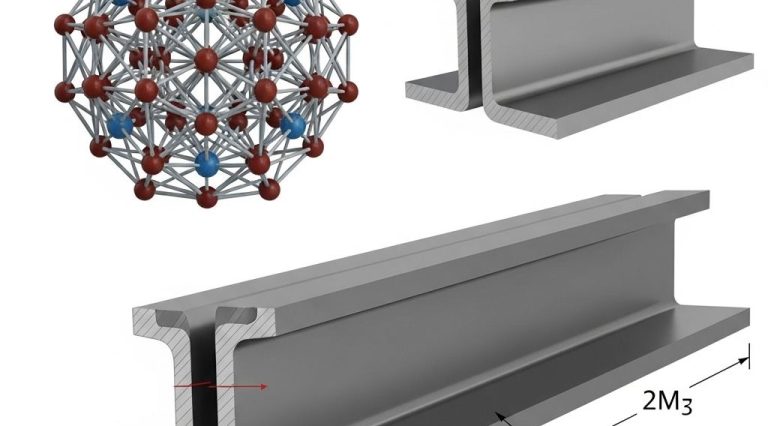

2. Finite Element Analysis (FEA) Tools

Finite Element Analysis is critical for evaluating how a design will perform under various physical conditions. FEA software helps engineers simulate stress, strain, and thermal effects on materials and structures. Leading FEA tools include:

- ANSYS

- COMSOL Multiphysics

- Abaqus

- Nastran

Benefits of FEA

Utilizing FEA tools can provide several advantages:

- Identify potential design flaws early in the development process.

- Optimize material selection and geometry to enhance performance.

- Reduce the need for physical prototypes, saving time and costs.

3. 3D Printers

3D printing technology has revolutionized the prototyping process in mechanical engineering. It enables engineers to create complex geometries that are often impossible to manufacture with traditional methods. Some common applications of 3D printers include:

| Application | Material Used |

|---|---|

| Rapid Prototyping | PLA, ABS, Nylon |

| Functional Testing | Flexible TPU, Resin |

| End-Use Parts | Metal, High-Temperature Plastics |

4. Measurement Instruments

Accurate measurement is crucial in mechanical engineering, and having the right instruments is essential. Common measurement tools include:

- Micrometers

- Calipers

- Dial Indicators

- Laser Scanners

Choosing the Right Measurement Tool

When selecting measurement tools, consider the following:

- Precision requirements of your project.

- Material you are measuring.

- Environment (temperature, humidity) that may affect measurements.

5. Simulation Software

Simulation software enables engineers to predict how systems will behave under various conditions and loads. These tools are essential for performing dynamic simulations, thermal analysis, and fluid dynamics. Popular simulation software includes:

- MATLAB/Simulink

- OpenFOAM

- SimPack

- MSC Adams

Importance of Simulation

Simulation aids in:

- Enhancing performance through optimization.

- Minimizing the risk of failure in engineering designs.

- Accelerating the design process by providing insights that inform decisions.

6. CNC Machines

Computer Numerical Control (CNC) machines are essential for the precise manufacturing of components. They automate the machining process and are used for milling, turning, and drilling operations. Key types of CNC machines include:

- CNC Mills

- CNC Lathes

- CNC Routers

- CNC Plasma Cutters

Advantages of CNC Machining

CNC machining offers several benefits:

- High precision and repeatability.

- Ability to create complex shapes and designs.

- Reduced labor costs through automation.

7. Soldering and Welding Tools

For projects involving assembly and fabrication, soldering and welding tools are vital. They allow engineers to join materials effectively. The most common tools include:

- Welding Machines

- Soldering Irons

- Plasma Cutters

- Fume Extractors

Best Practices for Welding

To ensure quality in welding:

- Clean surfaces before starting.

- Choose the appropriate technique for the materials involved.

- Monitor temperature and environment during the process.

8. Robotics and Automation Systems

Incorporating robotics and automation into mechanical engineering projects can enhance efficiency and reduce human error. Key components include:

- Robotic Arms

- Automated Guided Vehicles (AGVs)

- Industrial Robots

Impact of Robotics on Engineering

Robotics technology can:

- Improve production speed and consistency.

- Allow for the execution of dangerous tasks safely.

- Facilitate the integration of IoT for smarter manufacturing.

9. Project Management Software

Effective management is crucial for successful engineering projects. Project management software helps engineers track progress, allocate resources, and collaborate with team members. Popular options include:

- Microsoft Project

- Trello

- Asana

- Jira

Key Features to Look For

When selecting project management software, consider:

- Ease of use and learning curve.

- Collaboration capabilities.

- Integration with other tools and platforms.

10. Quality Control Tools

Ensuring the quality of designs and products is a fundamental aspect of mechanical engineering. Quality control tools help maintain standards and compliance. Common tools include:

- Statistical Process Control (SPC) Software

- Inspection Tools

- Quality Management Systems (QMS)

Benefits of Effective Quality Control

Implementing quality control measures can:

- Reduce defects and waste.

- Enhance customer satisfaction.

- Improve regulatory compliance.

In conclusion, the toolkit of a mechanical engineer is diverse and continually evolving. By mastering these ten essential tools, engineers can enhance their capabilities, streamline processes, and contribute to innovative solutions in their field. Whether you are a seasoned professional or a newcomer to the field, understanding and utilizing these tools effectively will help you succeed in the dynamic world of mechanical engineering.

FAQ

What are the essential mechanical engineering tools for students?

Essential tools include a caliper, micrometer, torque wrench, CAD software, and a 3D printer.

How do I choose the right mechanical engineering tools?

Consider factors like the specific tasks you’ll perform, the materials you’ll work with, and your budget.

What is the importance of CAD software in mechanical engineering?

CAD software allows for precise design, modeling, and simulation, which are crucial in mechanical engineering projects.

Are hand tools still relevant in mechanical engineering?

Yes, hand tools like wrenches, screwdrivers, and pliers are essential for assembly and maintenance tasks.

What safety equipment should mechanical engineers use?

Safety glasses, gloves, and steel-toed boots are crucial to protect against injuries while using mechanical tools.

How can I maintain my mechanical engineering tools?

Regular cleaning, proper storage, and timely calibration are key to maintaining the longevity and accuracy of your tools.