As industries evolve towards more sustainable practices, innovative polymers are becoming essential. These materials not only enhance performance but also address environmental concerns, much like promotional bag ideas that focus on reducing plastic waste while offering functionality and style.

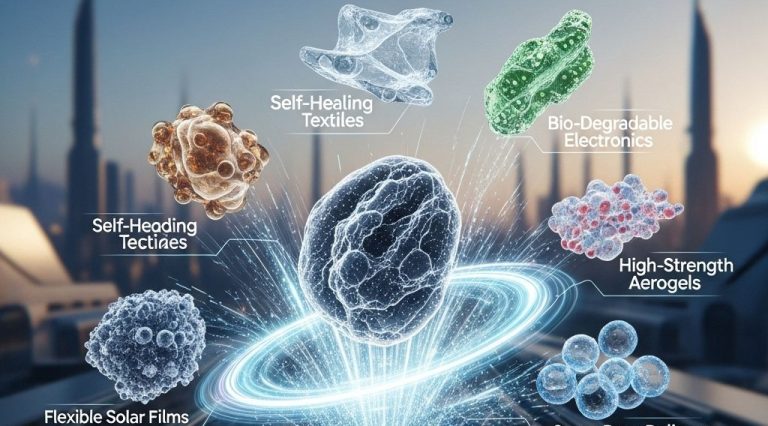

As we approach 2025, the world of materials science is undergoing a significant transformation, primarily driven by advances in polymer technology. Innovative polymers are at the forefront of this evolution, finding applications across various industries from healthcare to electronics. These materials are not only enhancing product performance but also sustainability, making them a focus for researchers and manufacturers alike.

The Rise of Biodegradable Polymers

One of the most pressing issues faced by humanity today is plastic waste. In response, biodegradable polymers are emerging as a viable solution. These materials are designed to decompose naturally, thus reducing environmental impact. Among the most innovative biodegradable polymers are:

- Polylactic Acid (PLA)

- Polyhydroxyalkanoates (PHA)

- Starch-based Plastics

Applications of Biodegradable Polymers

Biodegradable polymers are making waves in multiple sectors:

- Packaging: Used in food packaging to minimize waste.

- Textiles: Integrated into fabrics for environmentally friendly clothing.

- Medical devices: Employed in sutures and drug delivery systems.

Smart Polymers: The Future of Adaptive Materials

Smart polymers, also known as stimuli-responsive polymers, react to external stimuli like temperature, pH, or light. These materials can change their properties, making them ideal for applications in various fields.

Types of Smart Polymers

| Type | Stimulus | Example |

|---|---|---|

| Thermoresponsive | Temperature | Poly(N-isopropylacrylamide) |

| pH-responsive | pH changes | Poly(acrylic acid) |

| Light-responsive | UV light | Azobenzene derivatives |

Potential Uses of Smart Polymers

Smart polymers are paving the way for innovations such as:

- Drug delivery systems that release medication in response to body temperature.

- Self-healing materials that can repair minor damages on their own.

- Responsive coatings for optical devices that adjust based on light exposure.

Conductive Polymers: Merging Electronics with Flexibility

Conductive polymers have garnered attention for their ability to conduct electricity while retaining the advantageous properties of conventional polymers. This makes them particularly useful in the electronics industry.

Notable Conductive Polymers

Some of the most recognized conductive polymers include:

- Polyaniline (PANI)

- Poly(3,4-ethylenedioxythiophene) (PEDOT)

- Polypyrrole (PPy)

Applications in Electronics

Conductive polymers are employed in:

- Organic solar cells

- Flexible displays

- Wearable electronics

Recyclable Polyethylene: A Sustainable Alternative

Conventional polyethylene is one of the most widely used plastics, but its environmental impact is significant. The introduction of recyclable polyethylene aims to alleviate this issue.

Features of Recyclable Polyethylene

This innovative polymer exhibits remarkable properties:

- Can be recycled multiple times without losing structural integrity.

- Incorporates additives that enhance its recyclability.

Industry Impact

Recyclable polyethylene is set to transform:

- Consumer Goods: Companies are re-evaluating their packaging materials.

- Construction: Incorporation into building materials for sustainability.

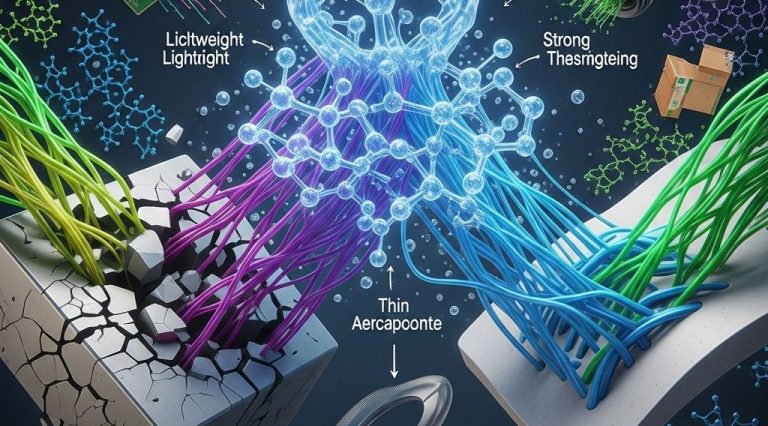

Thermoplastic Elastomers (TPE): The Best of Both Worlds

Thermoplastic elastomers combine the flexibility of rubber with the processing advantages of thermoplastics. Their versatility makes them suitable for a wide range of applications.

TPE Characteristics

Key characteristics include:

- Excellent elasticity and flexibility

- Easy processing and recycling

Applications of TPE

Common uses can be found in:

- Automotive parts, improving fuel efficiency

- Consumer products like grips and seals

Polymer Blends and Composites: Enhanced Performance

The development of polymer blends and composites has allowed for the combination of properties from different materials, leading to enhanced performance.

Types of Blends and Composites

Examples include:

- Polycarbonate/ABS blends for impact resistance

- Glass fiber-reinforced polymers for strength and durability

Benefits of Using Blends and Composites

Key advantages are:

- Customizable material properties

- Improved mechanical strength and thermal stability

Self-Healing Polymers: Repairing Damage Automatically

Self-healing polymers represent a revolutionary advancement in material science. These polymers can autonomously repair minor damages, extending the lifespan of products.

Mechanisms of Self-Healing

Two primary mechanisms include:

- Intrinsic healing: Uses reversible chemical bonds.

- Extrinsic healing: Requires the addition of healing agents.

Real-World Applications

Potential applications include:

- Coatings for electronics

- Automotive components

The Future of Polymers in Medicine

The role of polymers in medicine is expanding rapidly, with innovative materials being developed for use in drug delivery, implants, and tissue engineering.

Key Innovations

Breakthroughs in polymer technology are leading to:

- Controlled drug release systems

- Biocompatible scaffolds for tissue regeneration

Challenges Ahead

Despite the advancements, challenges such as biocompatibility and regulatory hurdles remain. Collaboration between material scientists, biomedical engineers, and healthcare professionals will be crucial for overcoming these barriers.

Conclusion

As we move closer to 2025, the landscape of polymer technology is evolving rapidly. The innovative polymers discussed above not only promise to enhance product performance but also address critical environmental challenges. From biodegradable materials to smart systems and self-healing capabilities, these advancements will undoubtedly shape the future of various industries. As a tech-savvy audience, it is essential to stay informed about these developments, as they will play a significant role in the sustainability and efficiency of our everyday products.

FAQ

What are innovative polymers and how are they changing industries in 2025?

Innovative polymers are advanced materials designed with enhanced properties for specific applications. In 2025, they are transforming industries such as healthcare, automotive, and electronics by offering improved performance, sustainability, and functionality.

What role do biodegradable polymers play in environmental sustainability by 2025?

Biodegradable polymers are playing a crucial role in reducing plastic waste by offering alternatives that break down naturally. By 2025, their use in packaging and consumer goods is expected to significantly lower environmental impact.

How are conductive polymers shaping the future of electronics in 2025?

Conductive polymers are revolutionizing electronics by enabling lightweight, flexible, and efficient components. By 2025, they will be integral in the development of wearable technology and advanced sensors.

What advancements in smart polymers can we expect to see by 2025?

Smart polymers, which respond to environmental stimuli, are expected to advance significantly by 2025. They will be used in drug delivery systems, self-healing materials, and adaptive clothing, enhancing functionality across various applications.

How are polymers contributing to advancements in healthcare by 2025?

Polymers are set to enhance healthcare through innovations in drug delivery, medical devices, and tissue engineering. By 2025, new polymer formulations will improve patient outcomes and reduce recovery times.

What are the implications of high-performance polymers for the automotive industry by 2025?

High-performance polymers are expected to play a key role in the automotive industry by 2025, contributing to lighter, more fuel-efficient vehicles while improving durability and reducing emissions.