In the competitive manufacturing landscape, leveraging innovative technologies is crucial for boosting productivity. Collaborative robots, or cobots, play a vital role in this transformation, allowing human workers to operate more efficiently alongside machines. For those involved in product design or packaging, integrating solutions like packaging mockups can further enhance the overall process, ensuring a seamless transition between manufacturing and marketing.

In today’s rapidly evolving manufacturing landscape, collaborative robots—commonly known as cobots—are becoming indispensable assets for enhancing productivity. Unlike traditional industrial robots, which often operate in isolation, cobots are designed to work alongside human workers, augmenting their capabilities and streamlining operations. This symbiotic relationship between humans and machines fosters a more efficient manufacturing environment. Here, we explore various ways cobots significantly boost productivity in manufacturing settings.

1. Enhanced Efficiency in Repetitive Tasks

Cobots excel at performing repetitive tasks that can be tedious and time-consuming for human workers. By taking over these monotonous activities, cobots allow human employees to focus on more complex and value-added tasks. This shift not only increases overall productivity but also helps in reducing worker fatigue.

Examples of Repetitive Tasks Handled by Cobots:

- Assembly line operations

- Quality control inspections

- Packaging and labeling

- Material handling

2. Improved Workplace Safety

Safety is paramount in manufacturing environments. Cobots are designed with advanced safety features that enable them to operate in close proximity to human workers without the risk of injury. By taking on hazardous tasks, cobots reduce the likelihood of workplace accidents and injuries, leading to a more efficient workflow.

Key Safety Features of Cobots:

| Feature | Description |

|---|---|

| Force Limiting | Cobots automatically reduce their force if they detect contact with a human. |

| Speed Adjustment | They can modulate their speed based on the proximity of human workers. |

| Environment Awareness | Many models are equipped with sensors to navigate and adjust to their surroundings. |

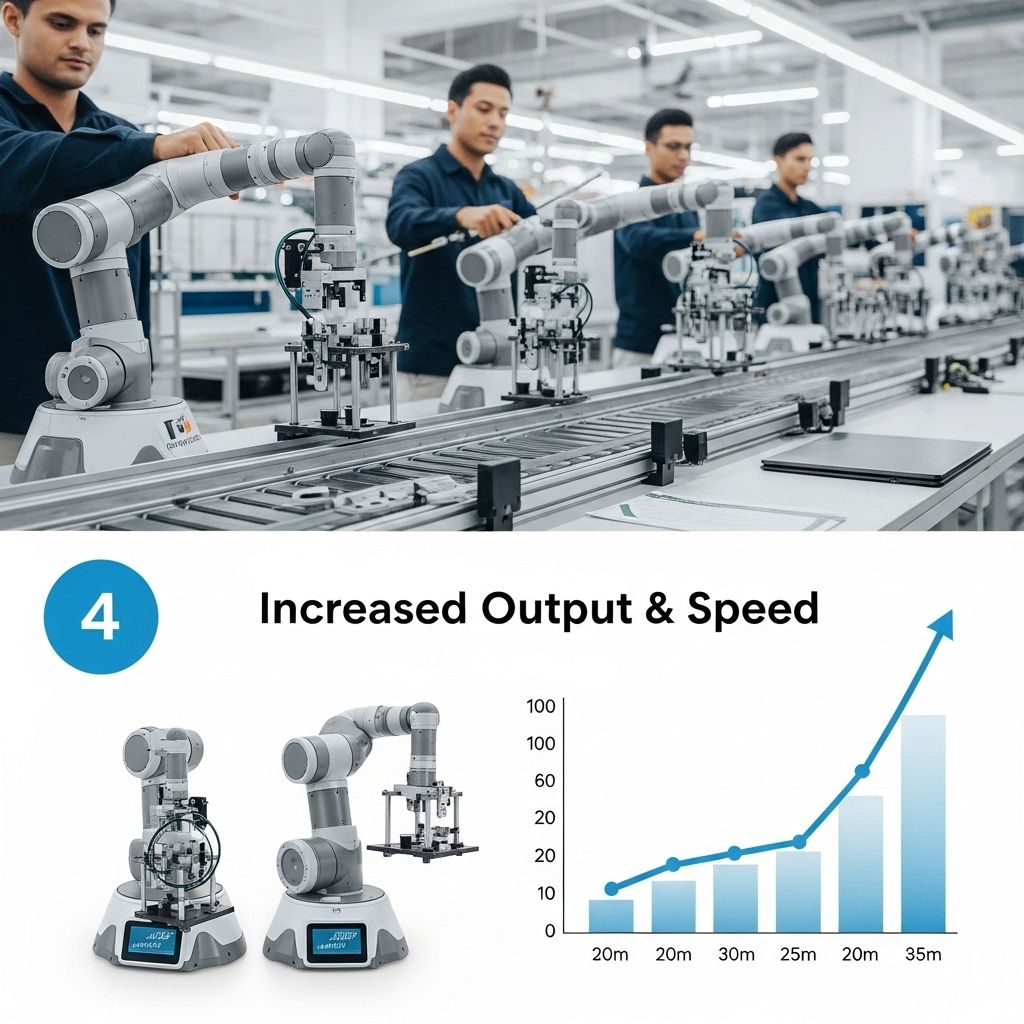

3. Flexibility and Adaptability

Cobots are inherently flexible and can be easily reprogrammed for different tasks. This adaptability is particularly useful in manufacturing settings where product lines frequently change or where customization is essential.

Benefits of Flexibility:

- Quick setup and reconfiguration minimize downtime.

- Ability to handle a variety of tasks reduces the need for multiple specialized machines.

- Scalability facilitates adjustment to changing production demands.

4. Data Collection and Analysis

Cobots can be equipped with sensors and software that gather valuable data during operations. This data can be analyzed to identify bottlenecks, improve processes, and enhance overall productivity.

Ways Data Collection Enhances Productivity:

- Real-Time Monitoring: Cobots provide live feedback on production metrics.

- Predictive Maintenance: Data can be used to schedule maintenance before issues arise.

- Performance Analytics: Understanding patterns enables informed decisions regarding workforce and resource allocation.

5. Cost-Effectiveness

Integrating cobots into manufacturing processes can lead to significant cost savings. While the initial investment may be considerable, the long-term benefits often outweigh costs due to increased efficiency and reduced labor expenses.

Cost-Saving Aspects of Cobots:

| Cost Aspect | Impact |

|---|---|

| Labor Costs | Reduced need for manual labor leads to lower payroll expenses. |

| Operational Efficiency | Streamlined processes result in lower production costs. |

| Training Costs | Users require less training time to interface with cobots compared to traditional robotics. |

Conclusion

The integration of collaborative robots in manufacturing not only transforms operational capabilities but also significantly enhances productivity. By effectively taking on repetitive tasks, improving workplace safety, providing flexibility, enabling data-driven decision making, and offering cost savings, cobots are paving the way for more efficient manufacturing processes. As technology continues to advance, the role of cobots in the industry is poised to grow even further, making them a vital component of the modern manufacturing ecosystem.

FAQ

What are cobots and how do they enhance manufacturing productivity?

Cobots, or collaborative robots, are designed to work alongside human operators. They enhance manufacturing productivity by automating repetitive tasks, reducing human error, and allowing workers to focus on more complex jobs.

How do cobots improve worker safety in manufacturing environments?

Cobots are equipped with advanced sensors and safety features that enable them to operate safely alongside human workers, minimizing the risk of accidents and injuries while boosting overall productivity.

Can cobots be easily integrated into existing manufacturing systems?

Yes, cobots are designed for easy integration into existing manufacturing processes, requiring minimal changes to workflow and allowing for quick deployment to enhance productivity.

What types of tasks can cobots perform in a manufacturing setting?

Cobots can perform a variety of tasks including assembly, packaging, quality control, and material handling, all of which contribute to increased efficiency and productivity.

How do cobots contribute to cost savings in manufacturing?

By automating tasks and improving efficiency, cobots can help reduce labor costs, minimize waste, and increase production speed, leading to significant cost savings for manufacturers.

What industries can benefit from implementing cobots in their manufacturing processes?

Various industries, including automotive, electronics, consumer goods, and pharmaceuticals, can benefit from cobots, as they help streamline operations and increase productivity across a wide range of manufacturing processes.