3D printing is not only reshaping the engineering landscape but is also a vibrant field for creative innovation. As the technology evolves, it opens up new avenues for design and problem-solving, making it essential for engineers to stay inspired. To ignite your creativity, explore design inspirations that demonstrate the artistic possibilities of this transformative tool.

In recent years, 3D printing has emerged as a transformative technology in various industries, with engineering at the forefront of this revolution. The ability to create complex structures and prototypes quickly and efficiently has changed the way engineers approach design, manufacturing, and problem-solving. This article delves into the various ways in which 3D printing is reshaping engineering, providing insights into its applications, benefits, and challenges.

1. Rapid Prototyping

One of the most significant impacts of 3D printing in engineering is its ability to facilitate rapid prototyping. Traditional prototyping methods often involve lengthy lead times and high costs. In contrast, 3D printing allows engineers to:

- Create prototypes in a fraction of the time.

- Experiment with multiple designs without the risk of significant financial loss.

- Quickly iterate on designs based on user feedback.

By reducing the time and cost associated with prototyping, engineers can bring their products to market faster, leading to increased innovation and competitiveness.

Benefits of Rapid Prototyping

| Benefit | Description |

|---|---|

| Speed | Shortens the design cycle significantly. |

| Cost-Effective | Reduces materials and labor costs associated with traditional methods. |

| Flexibility | Allows for easy modifications to designs. |

2. Customization and Personalization

3D printing enables engineers to create highly customized products tailored to specific user needs. This capability is particularly advantageous in sectors like healthcare, where personalized implants and prosthetics can be designed to fit individual patients perfectly.

Applications in Customization

- Healthcare: Custom prosthetics and dental implants.

- Consumer Products: Customized shoes and eyewear.

- Aerospace: Tailored components for aircraft and spacecraft.

The shift towards customization can lead to enhanced user satisfaction and improved performance of the final products.

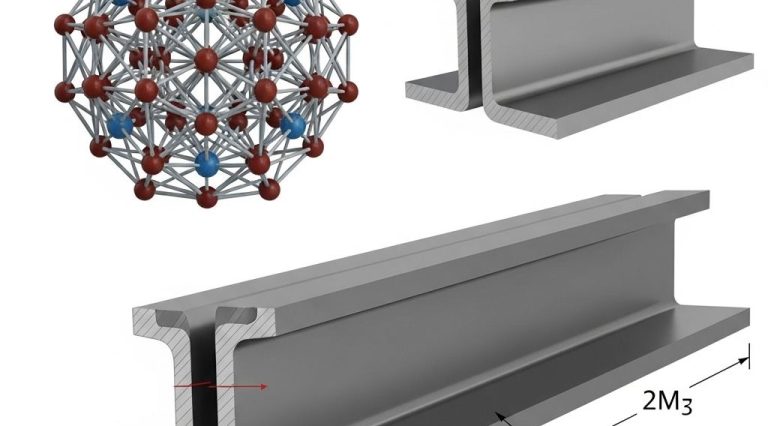

3. Complex Geometries

One of the standout features of 3D printing is its ability to create intricate geometries that are often impossible to achieve with traditional manufacturing methods. This capability unlocks new possibilities for engineering design, allowing for:

- Lightweight structures that maintain strength.

- Integration of multiple components into a single part, reducing assembly time.

- Innovative designs that optimize performance.

Examples of Complex Geometries

Some notable examples of complex geometries produced through 3D printing include:

- Topology optimized parts in automotive applications.

- Fluid flow systems with optimized channel designs.

- Heat exchangers with enhanced surface areas.

4. On-Demand Manufacturing

3D printing significantly enhances the concept of on-demand manufacturing by allowing engineers to produce parts as needed, reducing the need for large inventories. This approach can lead to:

- Reduced Waste: Only print what is necessary.

- Lower Storage Costs: Decreases the need for inventory space.

- Agility: Allows for quick adaptation to changing market demands.

Impact on Supply Chains

The rise of on-demand manufacturing through 3D printing can also transform supply chains by:

- Minimizing transportation costs through localized production.

- Reducing lead times associated with traditional manufacturing.

- Enabling a more responsive and flexible production model.

5. Sustainability and Material Efficiency

As sustainability becomes a critical concern in engineering, 3D printing provides a path toward more eco-friendly practices. The technology offers several advantages in terms of material efficiency and waste reduction:

- Generates less waste compared to subtractive manufacturing processes.

- Utilizes biodegradable and recyclable materials.

- Enables the use of composite materials for enhanced performance.

Examples of Sustainable Practices

Some organizations are already adopting sustainable 3D printing practices, such as:

- Using Recycled Materials: Integrating recycled plastics into printing processes.

- Energy Efficiency: Implementing energy-efficient printers and processes.

- Life Cycle Assessment: Evaluating the environmental impact of products from conception to disposal.

In summary, 3D printing is revolutionizing engineering in numerous ways, from enabling rapid prototyping and customization to supporting sustainability and complex design capabilities. As the technology continues to evolve, its potential to reshape industries will only grow, leading to innovations that we have yet to imagine.

FAQ

How does 3D printing enhance engineering design processes?

3D printing allows engineers to create rapid prototypes, enabling quicker iterations and improvements in design, leading to more innovative solutions.

What are the benefits of 3D printing in manufacturing engineering?

3D printing reduces material waste, lowers production costs, and shortens lead times, making it an efficient option for manufacturing engineering.

Can 3D printing be used for complex engineering projects?

Yes, 3D printing can produce intricate and complex geometries that traditional manufacturing methods may struggle to achieve, thus enhancing engineering capabilities.

What role does 3D printing play in prototyping for engineers?

3D printing facilitates rapid prototyping, allowing engineers to test and validate designs quickly, which accelerates the overall development cycle.

How is 3D printing changing the landscape of materials engineering?

3D printing is pushing the boundaries of materials engineering by enabling the use of advanced materials and composites that enhance product performance and functionality.

What industries are benefiting the most from 3D printing in engineering?

Industries such as aerospace, automotive, healthcare, and construction are significantly benefiting from 3D printing due to its ability to create customized and lightweight components.