As we approach 2025, the rise of collaborative robots, or cobots, stands to significantly transform industries. Designed to work alongside humans, these machines enhance productivity and ensure safety. For those looking to visualize innovative designs in product manufacturing, consider exploring mockup templates for bottles as part of your strategy.

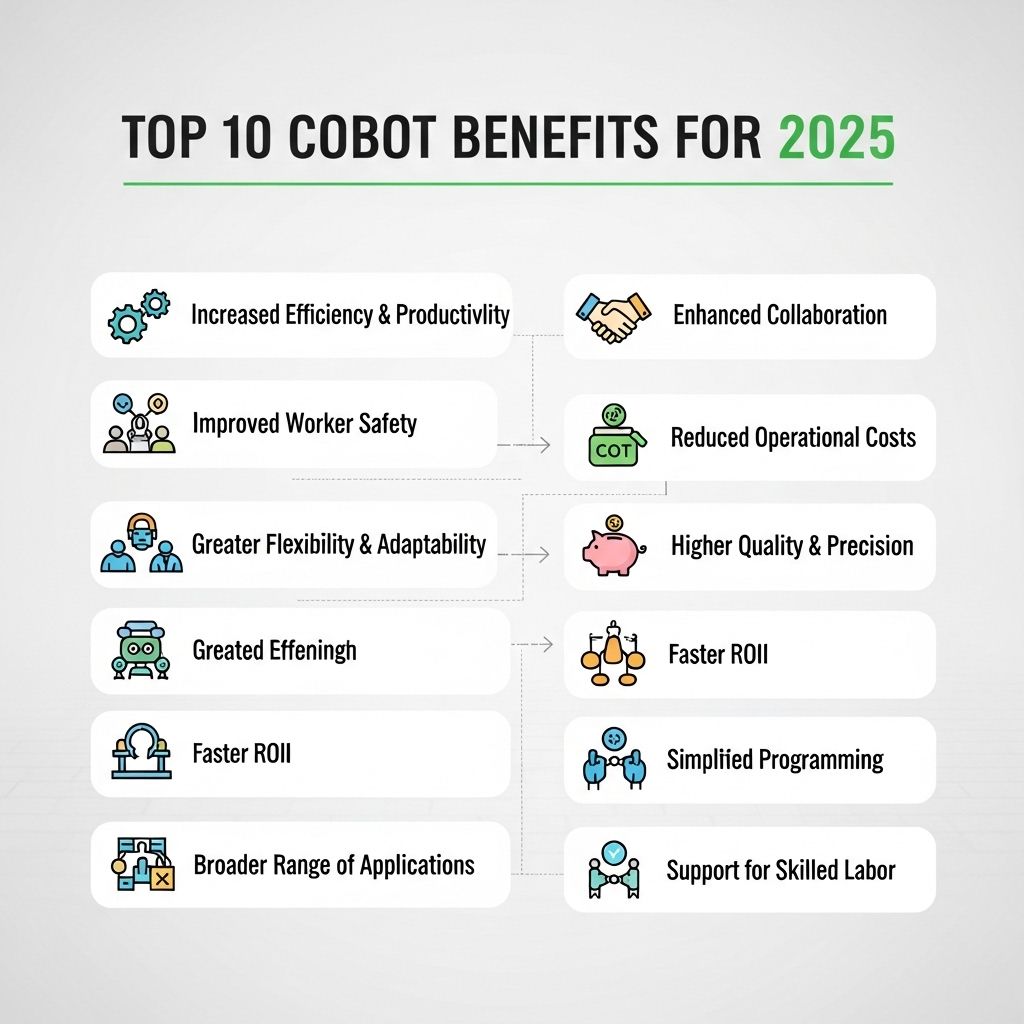

As we step into an era marked by rapid technological advancement, collaborative robots, or cobots, are becoming increasingly integral to manufacturing and service industries. These intelligent machines are designed to work alongside human workers, enhancing productivity while ensuring safety and efficiency. In this article, we’ll explore the top ten benefits of cobots as we head towards 2025, shedding light on how they are revolutionizing workplaces and redefining human-robot interaction.

1. Enhanced Safety in the Workplace

Cobots are engineered to work collaboratively with humans, significantly reducing the risk of workplace accidents. Unlike traditional industrial robots, which often operate in isolated environments, cobots are equipped with advanced sensors and safety features that allow them to interact safely with human coworkers.

Key Features Contributing to Safety:

- Force-limiting technology that prevents harm in case of accidental contact.

- Real-time monitoring systems that detect human presence.

- Built-in emergency stop mechanisms.

2. Increased Productivity

The integration of cobots into the workforce has shown a marked increase in productivity. With the ability to handle repetitive and mundane tasks, cobots free human workers to focus on more complex and creative aspects of their jobs.

How Cobots Boost Productivity:

- 24/7 operation without breaks.

- Reduction of human error in repetitive tasks.

- Efficient task execution leading to faster turnaround times.

3. Cost-Effectiveness

Investing in cobots can lead to substantial savings for businesses. They are generally less expensive than traditional robotic systems, both in terms of initial investment and operational costs.

Areas of Cost Savings:

| Area | Traditional Robots | Cobots |

|---|---|---|

| Initial Cost | High | Moderate |

| Installation Cost | High | Low |

| Maintenance | High | Low |

| Training | Extensive | Minimal |

4. Flexibility and Adaptability

Cobots can easily be reprogrammed and redeployed to handle various tasks. This adaptability makes them ideal for businesses facing fluctuating demands or those looking to diversify their offerings.

Examples of Flexibility:

- Switching from assembly tasks to quality control inspections.

- Reconfiguring for different product lines with minimal downtime.

- Collaborative tasks that change based on project needs.

5. Improved Quality Control

Quality control is paramount in production. Cobots can be programmed to conduct inspections that ensure products meet quality standards, thereby reducing defects and enhancing overall product quality.

Benefits of Automated Quality Control:

- Consistent and accurate inspections.

- Real-time data collection for analysis.

- Quick identification of production issues.

6. Ease of Use and Integration

Cobots are designed to be user-friendly, often requiring little to no programming skills to operate. This ease of use facilitates seamless integration into existing workflows.

Integration Benefits:

- Short learning curves for employees.

- Minimal disruption to existing processes.

- Quick return on investment.

7. Enhanced Worker Satisfaction

By alleviating humans from monotonous tasks, cobots can enhance job satisfaction among employees. This leads to a more motivated workforce and lower turnover rates.

Factors Contributing to Worker Satisfaction:

- Opportunities for skill development.

- Reduced physical strain and fatigue.

- Increased focus on meaningful work.

8. Scalability

Cobots provide businesses with the ability to scale operations up or down without significant investment or restructuring. This scalability makes them an attractive option for companies aiming for growth.

Scalability Advantages:

- Easy addition of more units as demand increases.

- Capability to downsize operations without major losses.

- Flexibility to adjust to market changes.

9. Data Collection and Analytics

Cobots can gather valuable data during their operations, providing insights that can be used for process optimization and decision-making. This analytical capability is crucial for businesses looking to improve efficiency.

Data Utilization:

- Tracking production metrics.

- Identifying bottlenecks in workflows.

- Enhancing inventory management.

10. Positive Impact on the Environment

Finally, cobots contribute to sustainability initiatives by optimizing resource use and reducing waste. Their precise operations minimize material waste, and their efficiency can lower energy consumption.

Environmental Benefits:

- Lower emissions compared to traditional manufacturing methods.

- Reduced material waste and better resource management.

- Support for green manufacturing practices.

Conclusion

As we move towards 2025, the benefits of collaborative robots are becoming ever more apparent. From enhanced safety and productivity to cost savings and environmental benefits, cobots are set to play an essential role in shaping the future of work. Businesses that adopt these technologies will not only gain a competitive edge but also contribute to creating a more efficient, safe, and sustainable environment.

FAQ

What are the main benefits of using cobots in manufacturing?

Cobots enhance productivity by collaborating with human workers, improving efficiency and reducing production time.

How do cobots improve workplace safety?

Cobots are designed to work alongside humans, minimizing the risk of accidents and injuries by taking over dangerous tasks.

Can cobots be easily integrated into existing workflows?

Yes, cobots are designed for easy integration and can be deployed quickly without extensive modifications to existing processes.

What role do cobots play in reducing operational costs?

By automating repetitive tasks, cobots help reduce labor costs and increase overall productivity, leading to lower operational expenses.

How do cobots contribute to flexibility in production?

Cobots can be easily reprogrammed and adapted to different tasks, allowing manufacturers to respond quickly to changing production needs.

What is the expected impact of cobots on employment in the future?

Cobots are expected to complement human workers rather than replace them, creating new job opportunities and enhancing skilled labor roles.